Toutes les catégorie

Bienvenue chez Imlab !

Depuis 1993, nous distribuons des équipements et des balances pour les laboratoires, l’industrie, l’agroalimentaire, …

Nos marques

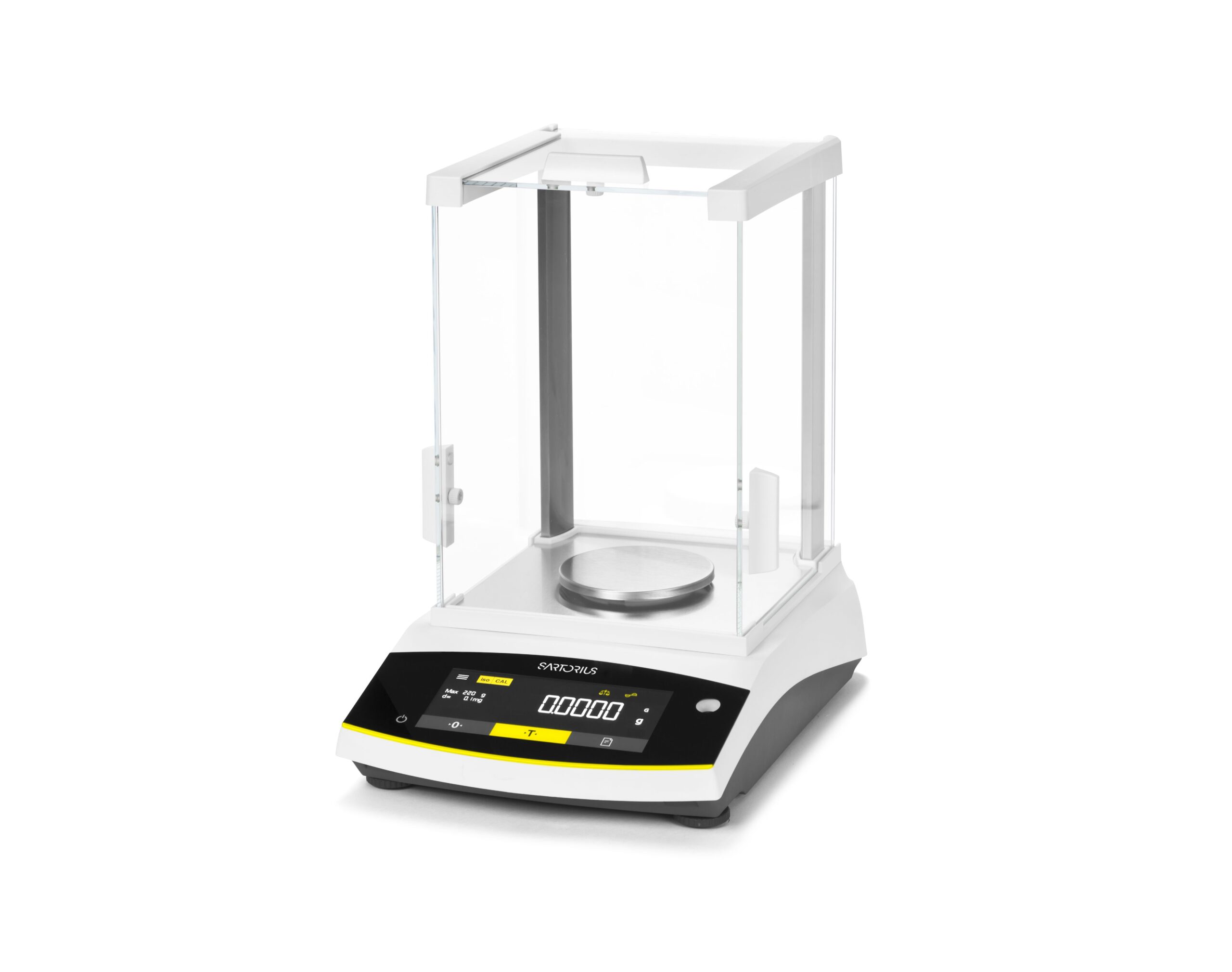

Produits populaires

Des produits de haute qualité et le meilleur service depuis 30 ans

Rien que le meilleur sur le marché

Plus de 10.000 produits et leurs accessoires qui conforment aux normes de sécurité et aux exigences de qualité les plus strictes.

En savoir plusService personnalisé

Il est important à nos yeux d’entretenir une étroite collaboration avec nos clients.

En savoir plusExpédition gratuite

Une expédition gratuite pour un achat en webshop de > 400,00 € (sauf livraison sur palette).

LivraisonCatégories populaires

Produits en promotion

Besoin de conseils ?

Posez votre question à nos spécialistes, nous serons heureux de vous aider !